INLINE AND OFFLINE SOLUTION FOR PLATE CLEANING

Cleaning the plates during the print job costs time and money and the print quality deteriorates.

- It is possible to clean inline within a running job. The causes can be dust contamination or dried ink.

We use a manual or automatic Quick Plate Cleaner (QPC) for this purpose. - Furthermore, there is the possibility to clean the plates offline at the end of a print job, this is done with our Final Plate Cleaner (FPC)

Advantages:

- Increase of production safety

- Contactless cleaning increases the service life of the plates

- Defined water and detergent consumption

- Machine operator can take over other tasks

QUICK-PLATE CLEANER (AUTOMATIC)

1. Removal of dust particles on the plate at the request of the machine operator while the machine is running.

- Increase of quality and reduction of machine downtimes due to dust

2. Continuous, automatic cleaning of the plate while the machine is running.

- Especially for halftone printing, reduction of machine downtimes due to dried ink on the plate

--> No waste sheets are produced

HOW IS THE SYSTEM STRUCTURED

1. The cleaning head is placed on the outlet side of the printing unit. The plate is inked directly after the washing process. This means that there are no marks in the print image.

2. The cleaning head is mounted on a guide rail and is moved along the printing cylinder by an electric motor.

3. On one side outside the working width is a washing station for the washing head.

WHAT ARE THE ADVANTAGES:

Advantages of the system:

1. The cleaning head is automatically cleaned in the machine.

- Longer use of a cleaning head without replacement

- Reduction of spare part costs

2. The cleaning head can be adjusted motor-driven, tenth of a millimetre exactly to the thickness of the plate. This is done centrally via the control panel for all cleaning heads.

- No setup required for each individual job.

Production and quality advantages:

- Reduction of machine stop times - thus higher machine output

- Less rejects due to quality problems (dust)

- Consistent quality for halftone printing

WHAT DOES THE SYSTEM LOOK LIKE?

1. spot cleaning

The cleaning head moves 1 time back and forth along the plate cylinder. During cleaning, there is no rotation. The cleaning head is cleaned automatically after use.

2. automatic mode

The cleaning head moves 1 time back and forth along the plate cylinder. Then the cleaning head is turned one step further to a clean spot. After 14 passes, the cleaning head is automatically cleaned and starts again.

QUICK PLATE CLEANER MANUAL

- Each point of dust causes a machine stop to clean the plate cylinders.

- Valuable machine running time, i.e. production capacity is lost.

- Printing defects are no longer accepted by customers.

- Automatic cleaning systems require a higher investment.

- Retrofits often lead to interventions in the printing machines.

- The QPC Manual is a manual spot cleaning system to remove dust spots while the press is running.

- The investment is manageable.

- It can be retrofitted to many fixed printing presses.

- With a small investment valuable additional production capacity can be created.

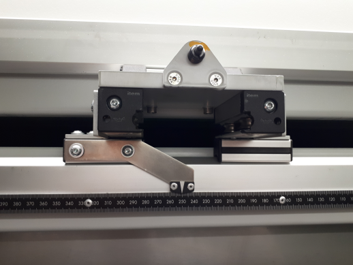

MODE OF OPERATION QPC

Manual cleaning of the plate cylinder as required!

Especially removal of dust spots when the printing machine is running at full speed, along the entire working width

Cleaning head adjusted to the plate cylinder.

FUNCTION OF THE CLEANING PROCESS

Manual cleaning of the plate cylinder by the operating personnel

Initial situation: Detection of contamination of the pressure at the machine operator at the test table or by a quality assurance system

- The machine operator introduces the QPC manual in the correct place in the printing unit concerned.

- This is done using a measuring scale attached to the QPC manual.

- With gentle pressure on the cleaning arm while the machine is running, the contamination on the plate cylinder can be removed.

- A defined contact pressure is guaranteed by a mechanical stop so that no marks are made on the print image.

The "park position" of the cleaning arm is placed outside the direct working area.

The "park position" is monitored by a safety switch.